Exploring the Advantages of Seamless Steel Tubes in Architectural Design

Exploring the Advantages of Seamless Steel Tubes in Architectural Design

In the ever-evolving world of architecture, the materials we choose can significantly impact both the aesthetics and functionality of a structure. Among these materials, **seamless steel tubes** have emerged as a favorite for architects and builders alike. This article will explore the many benefits of using seamless steel tubes in architectural design, from their superior strength to their aesthetic versatility, and how they can enhance the integrity of any construction project.

Table of Contents

- 1. Introduction to Seamless Steel Tubes

- 2. The Structural Benefits of Seamless Steel Tubes

- 2.1 High Strength-to-Weight Ratio

- 2.2 Resistance to Corrosion and Wear

- 3. Aesthetic Versatility in Architectural Design

- 3.1 Modern and Industrial Aesthetic

- 3.2 Customization and Finishing Options

- 4. Applications of Seamless Steel Tubes in Architecture

- 4.1 Structural Frameworks

- 4.2 Decorative Elements and Facades

- 5. Environmental Considerations of Seamless Steel

- 6. Economic Advantages of Using Seamless Steel Tubes

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to Seamless Steel Tubes

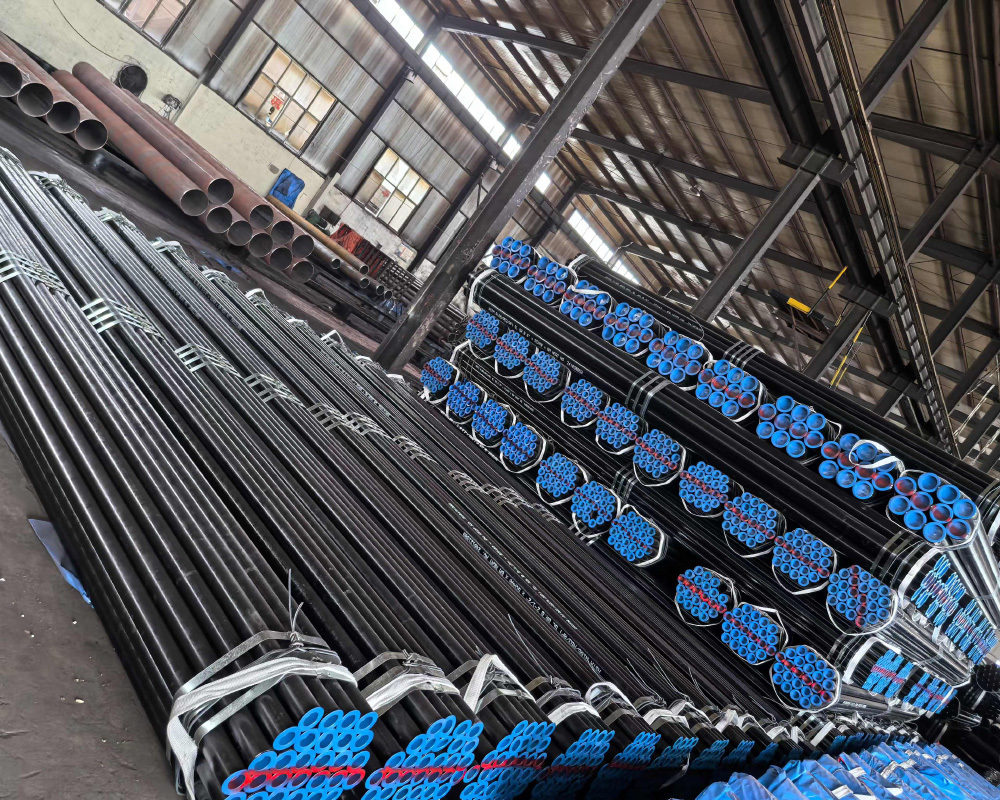

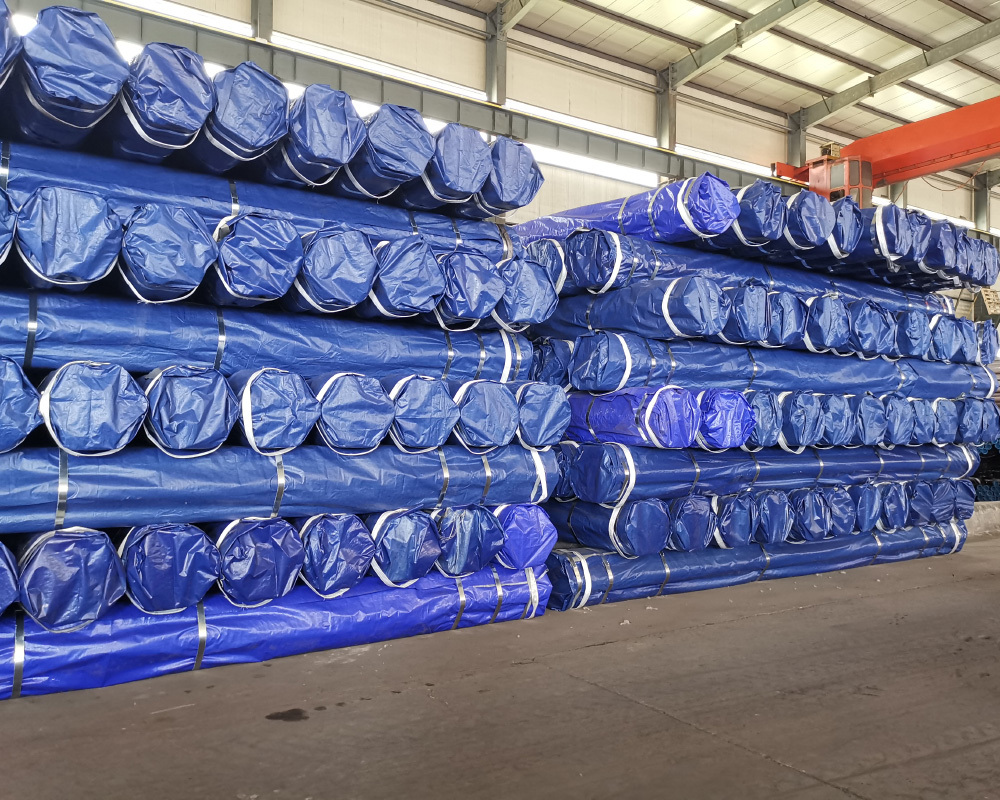

Seamless steel tubes are manufactured from solid round steel billets, which are heated and then stretched over a mandrel to create a tube without seams or welds. This process results in a stronger, more reliable product that is less prone to failure. The lack of seams in these tubes directly contributes to their increasing popularity in architectural and construction applications.

2. The Structural Benefits of Seamless Steel Tubes

When it comes to structural integrity, seamless steel tubes offer unparalleled advantages that set them apart from welded counterparts.

2.1 High Strength-to-Weight Ratio

One of the standout features of seamless steel tubes is their **high strength-to-weight ratio**. This property allows architects and engineers to design structures that are both strong and lightweight, making them ideal for high-rise buildings and other large constructions. The ability to use less material without sacrificing strength leads to significant savings in both cost and weight, ultimately enhancing the overall efficiency of building projects.

2.2 Resistance to Corrosion and Wear

Seamless steel tubes are also highly resistant to **corrosion and wear**, especially when treated with appropriate coatings or finishes. This resistance extends the lifespan of the materials used in construction, reducing maintenance costs and ensuring the longevity of architectural designs. In regions exposed to harsh weather conditions, seamless steel tubes provide a reliable and durable option that stands the test of time.

3. Aesthetic Versatility in Architectural Design

Beyond their structural benefits, seamless steel tubes bring a unique aesthetic to architectural designs. Their clean lines and modern look can enhance various design styles, from minimalist to industrial.

3.1 Modern and Industrial Aesthetic

The sleek appearance of seamless steel tubes lends itself well to contemporary architecture. They can create striking visual lines and structures that draw the eye and make a statement. This modern aesthetic is particularly favored in urban settings, where the combination of steel and glass is prevalent.

3.2 Customization and Finishing Options

Seamless steel tubes can be easily customized with various finishes, allowing architects to incorporate them into designs while maintaining a specific aesthetic vision. They can be painted, powder-coated, or left with a natural steel finish, providing flexibility for creative expression.

4. Applications of Seamless Steel Tubes in Architecture

Seamless steel tubes have a broad range of applications in architectural projects, which further underscores their versatility and effectiveness.

4.1 Structural Frameworks

Many architects use seamless steel tubes as key elements in structural frameworks. Their strength and durability make them ideal for bearing loads in buildings, bridges, and other infrastructures. This application not only enhances safety but also allows for innovative design solutions that can push the boundaries of traditional construction.

4.2 Decorative Elements and Facades

In addition to their structural roles, seamless steel tubes are commonly used for **decorative elements** and facades. Their aesthetic appeal can transform an ordinary building into an architectural marvel. Whether used in railings, canopies, or as part of a building's exterior, seamless steel tubes add character and sophistication.

5. Environmental Considerations of Seamless Steel

As the construction industry moves toward more sustainable practices, the **environmental impact** of building materials has become increasingly important. Seamless steel tubes are recyclable, making them an environmentally friendly option. Choosing steel contributes to a circular economy, as old steel can be melted down and repurposed without losing quality.

6. Economic Advantages of Using Seamless Steel Tubes

Incorporating seamless steel tubes into architectural projects can lead to significant economic benefits. Their durability reduces the need for frequent repairs and replacements, resulting in lower long-term maintenance costs. Additionally, their lightweight nature can reduce transportation and installation expenses, providing a cost-effective solution for builders.

7. Frequently Asked Questions

7.1 What are seamless steel tubes made of?

Seamless steel tubes are typically made from carbon steel or alloy steel, which provides excellent strength and durability. The material can vary based on the specific application and requirements of the structure.

7.2 How do seamless steel tubes compare to welded tubes?

Seamless steel tubes offer superior strength, consistency, and resistance to corrosion compared to welded tubes. The absence of welds means there are no weak points in the tube, making them more reliable for structural applications.

7.3 Are seamless steel tubes suitable for all climates?

Yes, seamless steel tubes can be treated or coated to withstand various environmental conditions, including extreme temperatures and humidity levels. Their durability makes them a suitable choice for diverse climates.

7.4 Can seamless steel tubes be customized?

Absolutely! Seamless steel tubes can be customized in terms of size, shape, and finish, allowing them to fit a wide range of design requirements and aesthetic preferences.

7.5 What is the lifespan of seamless steel tubes?

With proper treatment and maintenance, seamless steel tubes can last for decades. Their resistance to corrosion and wear greatly enhances their durability and lifespan compared to other materials.

8. Conclusion

In conclusion, the benefits of using seamless steel tubes in architecture are profound and multifaceted. Their superior strength, aesthetic versatility, and durability make them an outstanding choice for modern architectural projects. As the industry continues to embrace innovative materials and sustainable practices, seamless steel tubes will undoubtedly remain at the forefront of architectural design. By incorporating these tubes, architects and builders can not only enhance the structural integrity of their projects but also create visually stunning designs that stand the test of time.

TAG:

Previous:

Related Posts

Exploring the Advantages of Seamless Steel Tubes in Architectural Design