Understanding Seamless Tubes: The Backbone of Modern Construction

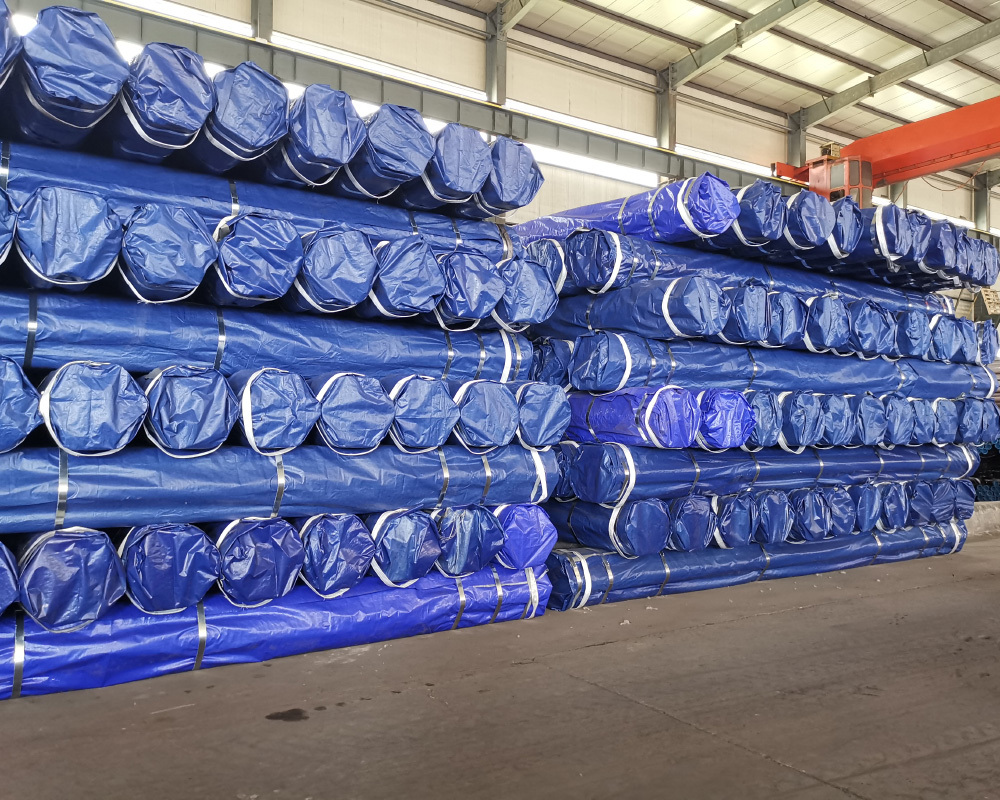

Seamless tubes, as the name implies, are tubes without any welded seams, which makes them particularly advantageous in various construction applications. Their structural integrity and uniformity are crucial for maintaining the strength and reliability of construction projects. Unlike welded tubes, which can be prone to weaknesses at the joints, seamless tubes are manufactured as a single piece, w

Seamless tubes, as the name implies, are tubes without any welded seams, which makes them particularly advantageous in various construction applications. Their structural integrity and uniformity are crucial for maintaining the strength and reliability of construction projects. Unlike welded tubes, which can be prone to weaknesses at the joints, seamless tubes are manufactured as a single piece, which minimizes the risk of failure under pressure.

The manufacturing process of seamless tubes typically involves several key steps. Initially, a solid steel billet is heated and then pierced to create a hollow tube. This tube undergoes further elongation and reduction processes using specialized equipment, including extrusion and rotary piercing. The end result is a tube that is not only seamless but also exhibits enhanced mechanical properties and a fine surface finish. These features make seamless tubes an attractive choice for numerous structural applications.

In the construction industry, seamless tubes find applications in various structural elements such as columns, beams, and support frameworks. Their ability to withstand high pressure makes them ideal for use in infrastructure projects, including bridges and industrial buildings. Additionally, seamless tubes are often used in high-temperature environments, such as in boilers and heat exchangers, due to their excellent resistance to thermal expansion and contraction.

Beyond structural applications, seamless tubes also serve aesthetic purposes in architectural designs. They can be used creatively in decorative railings, facades, and other features that require both strength and visual appeal. Their availability in various diameters and thicknesses allows architects and builders to select the most suitable options for specific design requirements.

Furthermore, the versatility of seamless tubes extends to their compatibility with different materials and finishes. They can be galvanized, coated, or painted to enhance their resistance to corrosion and improve their aesthetic qualities. This adaptability makes seamless tubes an excellent choice for a wide range of environments, from industrial settings to high-end residential projects.

In conclusion, seamless tubes play a vital role in the building and construction sector, providing essential strength, durability, and aesthetic value to various projects. Understanding their properties, manufacturing processes, and applications can greatly enhance your decision-making when it comes to selecting materials for your next construction endeavor. As the demand for innovative and sustainable building solutions continues to grow, seamless tubes will undoubtedly remain a foundational element of modern architecture.

The manufacturing process of seamless tubes typically involves several key steps. Initially, a solid steel billet is heated and then pierced to create a hollow tube. This tube undergoes further elongation and reduction processes using specialized equipment, including extrusion and rotary piercing. The end result is a tube that is not only seamless but also exhibits enhanced mechanical properties and a fine surface finish. These features make seamless tubes an attractive choice for numerous structural applications.

In the construction industry, seamless tubes find applications in various structural elements such as columns, beams, and support frameworks. Their ability to withstand high pressure makes them ideal for use in infrastructure projects, including bridges and industrial buildings. Additionally, seamless tubes are often used in high-temperature environments, such as in boilers and heat exchangers, due to their excellent resistance to thermal expansion and contraction.

Beyond structural applications, seamless tubes also serve aesthetic purposes in architectural designs. They can be used creatively in decorative railings, facades, and other features that require both strength and visual appeal. Their availability in various diameters and thicknesses allows architects and builders to select the most suitable options for specific design requirements.

Furthermore, the versatility of seamless tubes extends to their compatibility with different materials and finishes. They can be galvanized, coated, or painted to enhance their resistance to corrosion and improve their aesthetic qualities. This adaptability makes seamless tubes an excellent choice for a wide range of environments, from industrial settings to high-end residential projects.

In conclusion, seamless tubes play a vital role in the building and construction sector, providing essential strength, durability, and aesthetic value to various projects. Understanding their properties, manufacturing processes, and applications can greatly enhance your decision-making when it comes to selecting materials for your next construction endeavor. As the demand for innovative and sustainable building solutions continues to grow, seamless tubes will undoubtedly remain a foundational element of modern architecture.

TAG:

Previous

Next

Previous:

Next:

Related Posts

Understanding Seamless Tubes: The Backbone of Modern Construction

Seamless tubes, as the name implies, are tubes without any welded seams, which makes them particularly advantageous in various construction applications. Their structural integrity and uniformity are crucial for maintaining the strength and reliability of construction projects. Unlike welded tubes, which can be prone to weaknesses at the joints, seamless tubes are manufactured as a single piece, w