The Essential Guide to Seamless Steel Tubes in Construction

Seamless steel tubes are vital components in the construction and decoration materials sector, particularly in building applications. Unlike welded steel pipes, seamless tubes are manufactured without joints, making them stronger and more reliable for various structural and mechanical applications. This article aims to provide a comprehensive overview of seamless steel tubes, discussing their prod

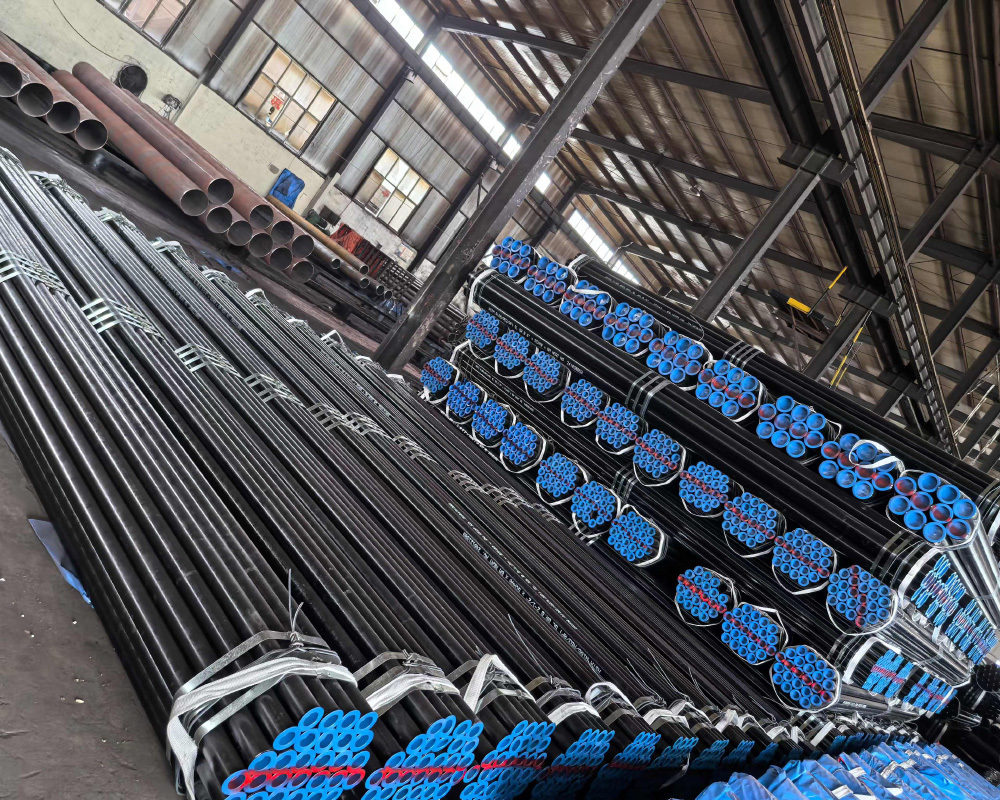

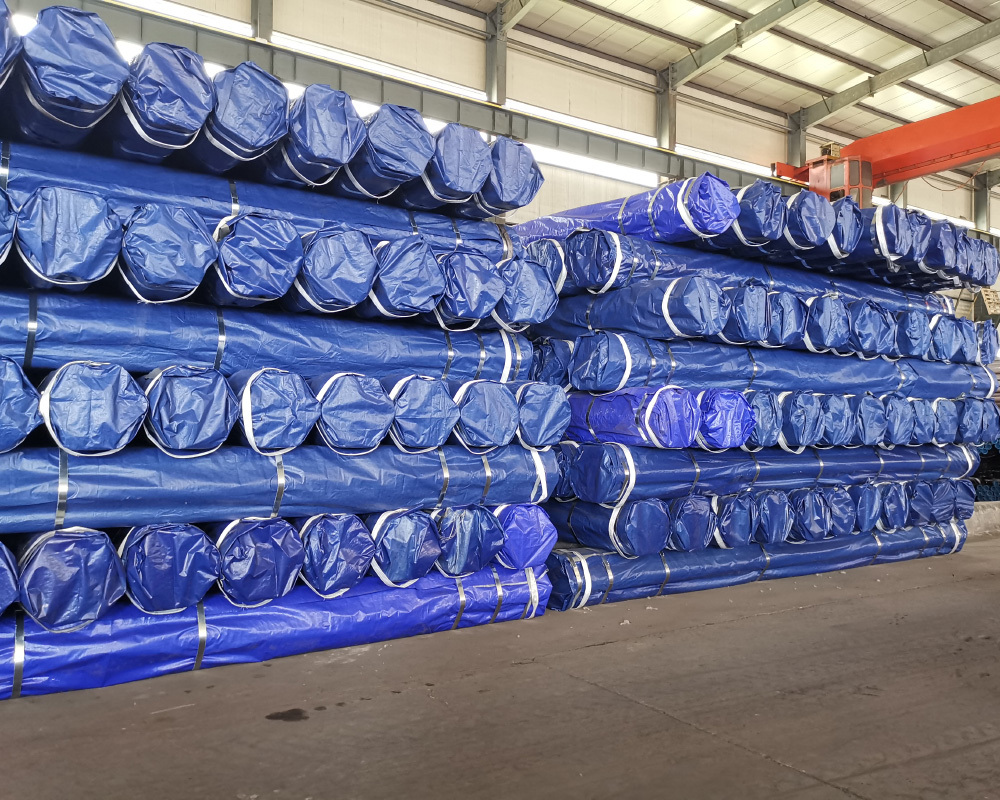

Seamless steel tubes are vital components in the construction and decoration materials sector, particularly in building applications. Unlike welded steel pipes, seamless tubes are manufactured without joints, making them stronger and more reliable for various structural and mechanical applications. This article aims to provide a comprehensive overview of seamless steel tubes, discussing their production methods, benefits, and typical applications in construction.

The manufacturing process of seamless steel tubes involves heating a solid round steel billet until it becomes malleable, followed by piercing it to create a hollow tube. The tube is then elongated and finished through processes such as extrusion or rotary piercing. This method eliminates the need for welds, resulting in a tube with uniform strength and durability, essential for high-pressure applications.

Seamless steel tubes are widely used in various construction projects, ranging from residential buildings to large infrastructure developments. Their strength and integrity make them suitable for structural applications such as columns, beams, and supports. In addition, they are often used in plumbing and heating systems, where pressure resistance is critical. Their smooth inner surface also minimizes the risk of corrosion and sediment build-up, ensuring a long-lasting performance.

One of the primary advantages of seamless steel tubes is their ability to withstand high-pressure environments. This characteristic is crucial for industries such as oil and gas, where seamless tubes are used in pipelines transporting fluids under extreme pressure. Additionally, they are highly resistant to cracking and deformation, even in harsh conditions, which increases the safety and reliability of constructions.

Another significant benefit is their versatility. Seamless steel tubes come in various sizes and wall thicknesses, making them adaptable for different project specifications. They can be easily customized to meet specific engineering requirements, allowing architects and builders to make informed decisions when designing structures.

Furthermore, seamless steel tubes contribute positively to the sustainability of construction projects. Their longevity and durability reduce the need for frequent replacements, thereby minimizing waste and the environmental impact associated with manufacturing new materials.

In conclusion, seamless steel tubes play a crucial role in the construction industry due to their strength, versatility, and durability. Understanding their manufacturing process and applications can help professionals make informed choices that enhance the quality and safety of their projects. As the industry continues to evolve, the demand for reliable construction materials like seamless steel tubes will remain strong, ensuring their place in modern building practices.

The manufacturing process of seamless steel tubes involves heating a solid round steel billet until it becomes malleable, followed by piercing it to create a hollow tube. The tube is then elongated and finished through processes such as extrusion or rotary piercing. This method eliminates the need for welds, resulting in a tube with uniform strength and durability, essential for high-pressure applications.

Seamless steel tubes are widely used in various construction projects, ranging from residential buildings to large infrastructure developments. Their strength and integrity make them suitable for structural applications such as columns, beams, and supports. In addition, they are often used in plumbing and heating systems, where pressure resistance is critical. Their smooth inner surface also minimizes the risk of corrosion and sediment build-up, ensuring a long-lasting performance.

One of the primary advantages of seamless steel tubes is their ability to withstand high-pressure environments. This characteristic is crucial for industries such as oil and gas, where seamless tubes are used in pipelines transporting fluids under extreme pressure. Additionally, they are highly resistant to cracking and deformation, even in harsh conditions, which increases the safety and reliability of constructions.

Another significant benefit is their versatility. Seamless steel tubes come in various sizes and wall thicknesses, making them adaptable for different project specifications. They can be easily customized to meet specific engineering requirements, allowing architects and builders to make informed decisions when designing structures.

Furthermore, seamless steel tubes contribute positively to the sustainability of construction projects. Their longevity and durability reduce the need for frequent replacements, thereby minimizing waste and the environmental impact associated with manufacturing new materials.

In conclusion, seamless steel tubes play a crucial role in the construction industry due to their strength, versatility, and durability. Understanding their manufacturing process and applications can help professionals make informed choices that enhance the quality and safety of their projects. As the industry continues to evolve, the demand for reliable construction materials like seamless steel tubes will remain strong, ensuring their place in modern building practices.

TAG:

Previous:

Related Posts

The Essential Guide to Seamless Steel Tubes in Construction

Seamless steel tubes are vital components in the construction and decoration materials sector, particularly in building applications. Unlike welded steel pipes, seamless tubes are manufactured without joints, making them stronger and more reliable for various structural and mechanical applications. This article aims to provide a comprehensive overview of seamless steel tubes, discussing their prod