Why Seamless Steel Tubes Are Essential for Modern Construction

Why Seamless Steel Tubes Are Essential for Modern Construction

Table of Contents

Introduction

Understanding Seamless Steel Tubes

Advantages of Seamless Steel Tubes

Applications in Modern Construction

Seamless vs. Welded Steel Tubes

Manufacturing Process of Seamless Steel Tubes

Sustainability and Economics

The Future of Seamless Steel Tubes

Frequently Asked Ques

Why Seamless Steel Tubes Are Essential for Modern Construction

Table of Contents

- Introduction

- Understanding Seamless Steel Tubes

- Advantages of Seamless Steel Tubes

- Applications in Modern Construction

- Seamless vs. Welded Steel Tubes

- Manufacturing Process of Seamless Steel Tubes

- Sustainability and Economics

- The Future of Seamless Steel Tubes

- Frequently Asked Questions

- Conclusion

Introduction

In the evolving realm of construction, the materials used play a significant role in the success and longevity of any project. Among these, **seamless steel tubes** have emerged as a cornerstone in modern architectural practices. Their unique properties render them particularly well-suited for a variety of applications, making them indispensable in today's construction landscape. This article explores the reasons why seamless steel tubes are essential for modern construction, highlighting their benefits, applications, and advantages over other materials.

Understanding Seamless Steel Tubes

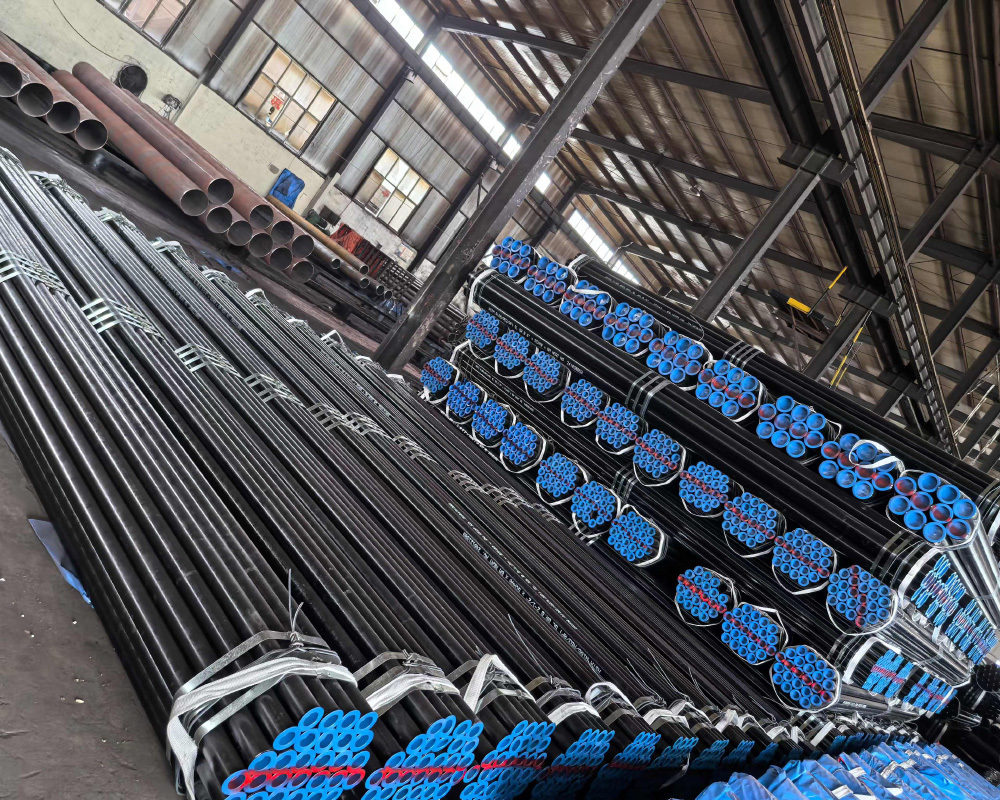

Seamless steel tubes are cylindrical structures manufactured from solid steel billets or bars, which are heated and then shaped into tubes without any seams. This method of production results in a smooth, continuous tube that boasts enhanced strength and durability. The absence of welds minimizes the risk of weak points, making seamless tubes a preferred choice in high-pressure and high-stress applications.

Key Characteristics of Seamless Steel Tubes

Seamless steel tubes are characterized by several features that contribute to their popularity:

- **High tensile strength**: Seamless tubes can withstand extreme pressures and temperatures.

- **Corrosion resistance**: Various coatings can be applied to enhance corrosion resistance.

- **Customization**: Seamless tubes can be manufactured in various diameters and wall thicknesses to meet specific project requirements.

Advantages of Seamless Steel Tubes

The advantages of using seamless steel tubes in construction are significant and multifaceted:

1. Superior Strength and Durability

Seamless steel tubes exhibit exceptional mechanical properties due to their solid structure. They are less prone to failure under stress, making them ideal for critical applications where safety is paramount.

2. Enhanced Safety Features

In construction, safety is a non-negotiable aspect. The reliability of seamless steel tubes significantly reduces the likelihood of catastrophic structural failures, ensuring that buildings and infrastructure remain secure over time.

3. Cost-Effectiveness

While seamless steel tubes may have a higher initial cost compared to welded alternatives, their durability and lower maintenance needs lead to decreased long-term costs. Projects using seamless tubes often enjoy enhanced lifespan and fewer replacements.

4. Versatility and Wide Application Range

Seamless tubes can be utilized across various sectors, including **oil and gas**, **automotive**, **construction**, and **manufacturing**. Their adaptability makes them an asset in any construction project.

5. Improved Aesthetic Appeal

Seamless tubes feature a smooth finish that can enhance the overall appearance of structures. Architects and designers favor them for projects where aesthetic considerations are paramount.

Applications in Modern Construction

Seamless steel tubes have a plethora of applications in modern construction, making them a versatile solution for various needs:

1. Structural Framework

Seamless tubes are frequently used in constructing the structural framework of buildings. Their strength allows them to support heavy loads, making them ideal for high-rise structures.

2. Piping Systems

In plumbing and HVAC systems, seamless steel tubes are used for piping due to their leak-proof characteristics. They ensure the safe and efficient transfer of fluids, making them the preferred choice for industrial and commercial applications.

3. Handrails and Guardrails

Seamless tubes are commonly employed in handrails and guardrails in commercial and residential buildings. Their robust nature ensures safety without compromising on design aesthetics.

4. Automotive Applications

In automotive manufacturing, seamless tubes are used for chassis and suspension components. Their strength and lightweight properties contribute to better performance and fuel efficiency.

5. Oil and Gas Infrastructure

The oil and gas industry relies on seamless steel tubes for drilling and pipeline construction. Their ability to withstand high pressures makes them essential for transporting hydrocarbons safely.

Seamless vs. Welded Steel Tubes

Understanding the difference between seamless and welded steel tubes can help in making informed material choices:

1. Structural Integrity

Seamless tubes offer enhanced structural integrity due to the absence of welds, which can be potential weak points. This makes seamless tubes more suitable for high-stress applications.

2. Pressure Ratings

Seamless tubes typically have higher pressure ratings compared to welded tubes, making them the preferred choice in applications involving high-pressure environments.

3. Manufacturing Process

The manufacturing process for seamless tubes is more complex, leading to higher costs. However, this investment pays off in terms of durability and performance.

Manufacturing Process of Seamless Steel Tubes

The manufacturing of seamless steel tubes involves a meticulous process to ensure quality and performance:

1. Billet Preparation

The process begins with the selection of high-quality steel billets. These billets are first heated to extreme temperatures to allow for easier shaping.

2. Piercing

Once heated, the billets undergo a piercing process, where a hole is created in the center, forming the initial tube shape.

3. Elongation and Expansion

The pierced billet is then elongated and expanded into a tube shape through rotary piercing or extrusion, enhancing its length and diameter.

4. Heat Treatment

The newly formed tube is heat-treated to improve its mechanical properties, ensuring that it meets the stringent requirements of various applications.

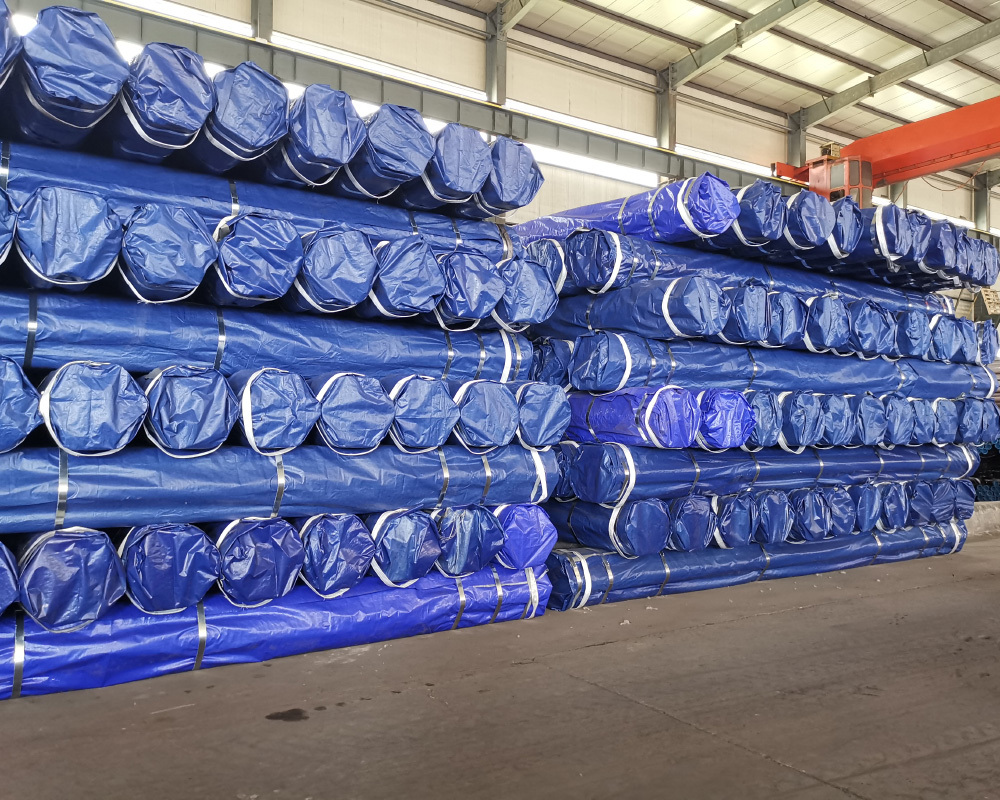

5. Finishing and Inspection

Finally, the tubes undergo various finishing processes, including surface treatment and inspection, to ensure they meet the specified standards for quality and performance.

Sustainability and Economics

The sustainability of seamless steel tubes is an increasingly important consideration in construction:

1. Recyclability

Steel is one of the most recycled materials globally. Seamless tubes can be reprocessed and reused, reducing the environmental impact associated with resource extraction.

2. Energy Efficiency

The production of seamless steel tubes can be optimized for energy efficiency, resulting in lower carbon emissions compared to other materials.

3. Long-Term Investment

While the upfront costs for seamless steel tubes may be higher, their durability and lower maintenance needs make them a sound long-term investment for construction projects.

The Future of Seamless Steel Tubes

As technology advances, the future of seamless steel tubes looks promising:

1. Innovations in Manufacturing

Emerging technologies, such as 3D printing and advanced metallurgy, may further enhance the properties and applications of seamless steel tubes, making them even more versatile.

2. Increased Demand in Emerging Markets

With rapid urbanization and industrial growth in emerging markets, the demand for seamless steel tubes is expected to increase, driving innovations and new applications.

3. Focus on Sustainability

The construction industry is progressively shifting towards sustainable practices. Seamless steel tubes' recyclability and longevity align with this trend, ensuring their relevance in future projects.

Frequently Asked Questions

1. What are seamless steel tubes made of?

Seamless steel tubes are primarily made from carbon steel or alloy steel and are created through a process that eliminates seams for enhanced strength.

2. How are seamless steel tubes different from welded tubes?

Seamless tubes do not have any welds, which provides them with superior strength and pressure ratings compared to welded steel tubes.

3. What are the primary applications of seamless steel tubes?

Seamless steel tubes are widely used in structural frameworks, piping systems, automotive components, and oil and gas infrastructure.

4. Are seamless steel tubes environmentally friendly?

Yes, seamless steel tubes are recyclable and energy-efficient, making them a sustainable choice in construction.

5. How can I choose the right seamless steel tube for my project?

Selecting the right seamless steel tube involves considering factors like the specific application, required strength, corrosion resistance, and diameter.

Conclusion

In conclusion, seamless steel tubes emerge as essential components in modern construction, offering remarkable strength, durability, and versatility. Their applications span across various sectors, from structural frameworks to piping systems, making them indispensable in today's architectural landscape. As the industry continues to evolve, the advantages of seamless steel tubes will only become more pronounced, solidifying their place as a preferred material in construction. By understanding their benefits and applications, construction professionals can make informed decisions that enhance the quality and longevity of their projects. The future of seamless steel tubes is bright, and their continued innovation will undoubtedly contribute to safer and more sustainable construction practices.

TAG:

Related Posts

Why Seamless Steel Tubes Are Essential for Modern Construction

Why Seamless Steel Tubes Are Essential for Modern Construction

Table of Contents

Introduction

Understanding Seamless Steel Tubes

Advantages of Seamless Steel Tubes

Applications in Modern Construction

Seamless vs. Welded Steel Tubes

Manufacturing Process of Seamless Steel Tubes

Sustainability and Economics

The Future of Seamless Steel Tubes

Frequently Asked Ques