How to Select the Right Diameter for Insulated PEX Pipe in Wood Boilers: A Comprehensive Guide

How to Select the Right Diameter for Insulated PEX Pipe in Wood Boilers

Table of Contents

Introduction to PEX Pipe in Wood Boilers

Understanding PEX Pipe and Its Applications

The Importance of Selecting the Right Diameter

Factors Influencing Diameter Selection for PEX Pipe

Flow Rate Requirements

Temperature Considerations

Length of Run

How to Select the Right Diameter for Insulated PEX Pipe in Wood Boilers

Table of Contents

- Introduction to PEX Pipe in Wood Boilers

- Understanding PEX Pipe and Its Applications

- The Importance of Selecting the Right Diameter

- Factors Influencing Diameter Selection for PEX Pipe

- Calculating the Right Diameter for Your System

- Common Mistakes in Diameter Selection

- Installation Tips for Insulated PEX Pipe

- Maintenance and Longevity of PEX Pipe Systems

- Conclusion

- FAQs About PEX Pipe Diameter Selection

Introduction to PEX Pipe in Wood Boilers

In the world of heating systems, the selection of proper materials can significantly influence efficiency and longevity. When it comes to wood boilers, **insulated PEX pipe** has emerged as a popular choice due to its flexibility, durability, and thermal efficiency. However, one critical aspect often overlooked is the diameter of the PEX pipe used. Choosing the correct diameter is paramount for ensuring that your heating system operates smoothly and efficiently.

Understanding PEX Pipe and Its Applications

**PEX** (cross-linked polyethylene) pipe is a versatile and robust plumbing material that has gained traction in various heating applications. Its inherent flexibility allows for easy installation, particularly in complex layouts where traditional piping systems may struggle. In wood boilers, PEX pipe serves as a conduit for transferring heated water, making its role vital in maintaining optimal system performance.

The Importance of Selecting the Right Diameter

The **diameter** of PEX pipe significantly impacts the overall performance of your wood boiler system. Selecting the right diameter ensures that water flows efficiently, maintaining necessary temperatures and reducing energy waste. A pipe that is too small may restrict flow, resulting in decreased efficiency and increased pump strain, while a pipe that is too large can lead to unnecessary heat loss.

Factors Influencing Diameter Selection for PEX Pipe

When determining the appropriate diameter for insulated PEX pipe in wood boilers, several factors must be considered.

Flow Rate Requirements

Understanding the **flow rate** required for your heating system is crucial. This rate is typically measured in gallons per minute (GPM) and indicates how much water needs to circulate in the system to maintain desired heating levels. As a general rule, a larger flow rate necessitates a larger diameter pipe to accommodate the increased water movement without causing pressure drops.

Temperature Considerations

**Temperature** is another vital factor to consider. Wood boilers operate at specific temperature ranges, and the diameter of the PEX pipe can affect heat retention. A wider diameter can lead to lower fluid velocity, potentially resulting in greater heat loss. Balancing temperature requirements with flow needs is essential for optimal system performance.

Length of Run

The **length of the run** refers to the distance that water travels through the PEX pipe from the boiler to the heating elements. Longer runs may require larger diameter pipes to mitigate pressure loss over distance. This consideration is especially important in larger properties where the distance from the boiler to the heating system can be substantial.

Insulation Type and Thickness

The **insulation** surrounding the PEX pipe also plays a role in determining the diameter. Properly insulated pipes can maintain heat more effectively, allowing for smaller diameters without significant heat loss. When selecting insulation, consider the type and thickness to ensure optimal performance.

Calculating the Right Diameter for Your System

To accurately calculate the right diameter for your insulated PEX pipe, follow these steps:

1. **Determine the Required Flow Rate**: Assess the heating needs of your space to establish the necessary flow rate.

2. **Assess System Length**: Measure the distance from the boiler to the furthest point in the heating system.

3. **Evaluate Temperature Requirements**: Take into account the operating temperature range of your wood boiler.

4. **Consult Manufacturer Guidelines**: Refer to the manufacturer's specifications on PEX pipe dimensions concerning flow rates and pressure losses.

By compiling this information, you can select a diameter that caters to the specific demands of your system, enhancing performance and efficiency.

Common Mistakes in Diameter Selection

When selecting the diameter for insulated PEX pipe, several common mistakes can lead to suboptimal performance:

1. **Overlooking Flow Rate Needs**: Many users underestimate flow rate requirements, leading to undersized pipes.

2. **Ignoring Pressure Loss**: Neglecting to account for pressure loss over distance can result in inefficient heating.

3. **Failing to Consider Future Needs**: As systems evolve, future demands may require upgrades that necessitate larger diameter pipes.

Avoiding these pitfalls will ensure that your wood boiler operates efficiently and effectively.

Installation Tips for Insulated PEX Pipe

Proper installation of insulated PEX pipe is crucial for maximizing performance. Here are some essential tips:

- **Maintain Proper Supports**: Ensure that the PEX pipe is adequately supported throughout its length to prevent sagging and kinking.

- **Avoid Sharp Bends**: When routing PEX pipe, avoid sharp bends that can impede flow. Use gentle curves whenever possible.

- **Inspect Insulation Integrity**: After installation, check that insulation is intact and covers all exposed areas to minimize heat loss.

- **Test the System**: Once installed, test the flow rate and temperature to ensure that everything operates as expected.

Maintenance and Longevity of PEX Pipe Systems

Regular maintenance of your insulated PEX pipe system is necessary for longevity. Here are some maintenance tips:

- **Inspect for Leaks**: Regularly check for leaks, particularly at joints and connections.

- **Monitor Temperature Settings**: Keep an eye on temperature settings to ensure they align with the system’s specifications.

- **Clean the System**: Periodically clean the system to remove any buildup that may restrict flow.

By following these maintenance tips, you can extend the lifespan of your PEX pipe system and ensure that it operates efficiently for years.

Conclusion

Selecting the right diameter for insulated PEX pipe in wood boilers is a critical process that directly influences the efficiency and performance of your heating system. By understanding the various factors impacting diameter selection—from flow rate and temperature to insulation and run length—you can make informed decisions that enhance your wood boiler's functionality. Proper installation and maintenance further contribute to the longevity and efficiency of your system. Armed with knowledge and careful planning, achieving optimal results in your heating setup is within reach.

FAQs About PEX Pipe Diameter Selection

1. What is the most common diameter for PEX pipe used in wood boilers?

The most commonly used diameters for PEX pipes in wood boilers typically range from 3/4 inch to 1 inch, depending on the system requirements.

2. How does pipe diameter affect heating efficiency?

A correctly sized pipe minimizes heat loss and maintains proper flow rates, significantly affecting the overall efficiency and performance of the heating system.

3. Can I use a smaller diameter pipe for a shorter run?

While a smaller diameter may suffice for shorter runs, it’s essential to ensure that flow rates and temperature requirements are still met to avoid inefficiency.

4. Are there specific brands of insulation recommended for PEX pipes?

Many brands offer high-quality insulation specifically designed for PEX pipes. Look for options that provide high thermal resistance and moisture protection.

5. How often should I inspect my PEX pipe system?

Regular inspections are recommended at least once a year to check for leaks, insulation integrity, and overall system performance.

TAG:

Related Posts

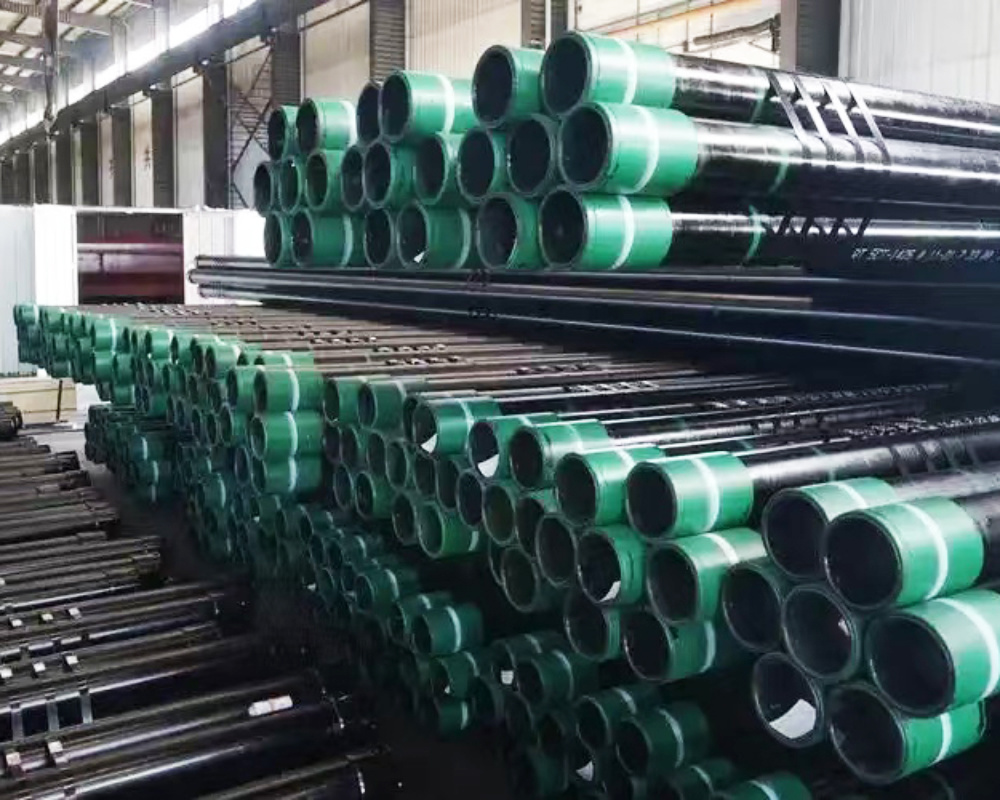

The Essential Guide to Seamless Black Steel Pipes in Construction

Seamless black steel pipes are a crucial component in various construction and decorative applications, particularly in the building materials sector. These pipes are manufactured without any joints, which offers a number of advantages over their welded counterparts. The absence of seams in seamless black steel pipes reduces the risk of leaks and increases their overall strength, making them ideal