Seamless Black Steel Pipe: A Reliable Choice for Structural Integrity

Seamless Black Steel Pipe: A Reliable Choice for Structural Integrity

Table of Contents

1. Introduction to Seamless Black Steel Pipes

2. Key Benefits of Seamless Black Steel Pipes

3. Applications of Seamless Black Steel Pipes in Various Industries

4. The Manufacturing Process of Seamless Black Steel Pipes

5. Industry Standards and Specifications

6. Maintenance Tips for Sea

Seamless Black Steel Pipe: A Reliable Choice for Structural Integrity

Table of Contents

- 1. Introduction to Seamless Black Steel Pipes

- 2. Key Benefits of Seamless Black Steel Pipes

- 3. Applications of Seamless Black Steel Pipes in Various Industries

- 4. The Manufacturing Process of Seamless Black Steel Pipes

- 5. Industry Standards and Specifications

- 6. Maintenance Tips for Seamless Black Steel Pipes

- 7. Cost-Effectiveness of Seamless Black Steel Pipes

- 8. Future Trends in Seamless Black Steel Pipe Usage

- 9. Frequently Asked Questions (FAQs)

- 10. Conclusion

1. Introduction to Seamless Black Steel Pipes

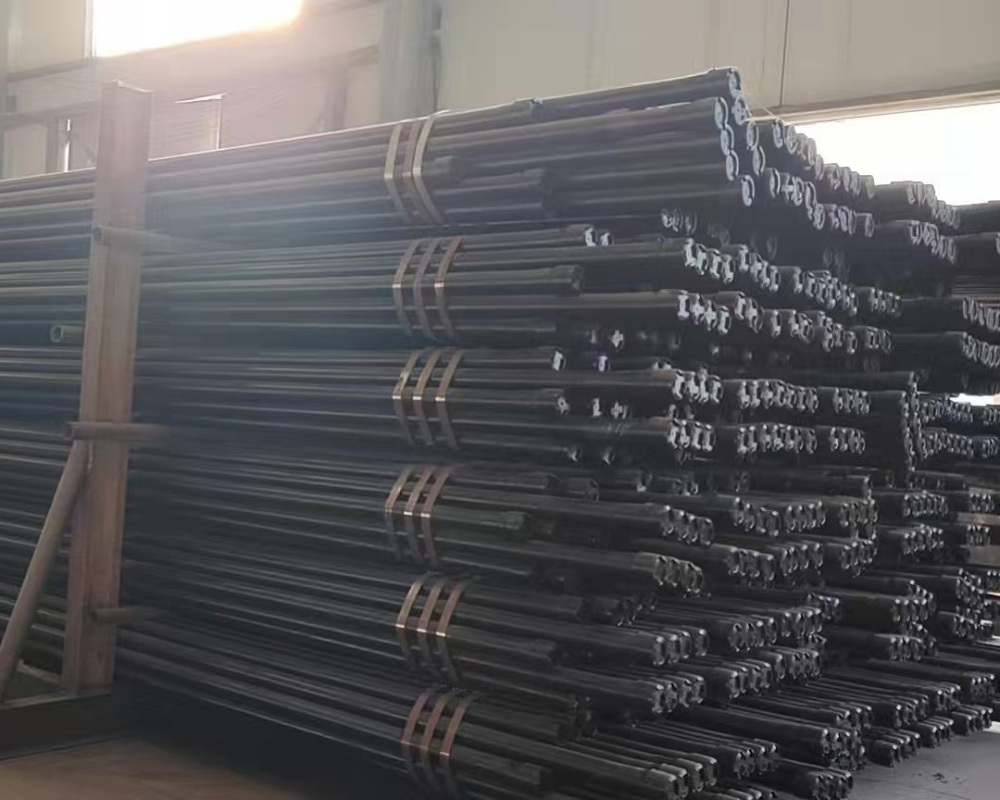

Seamless black steel pipes have become a cornerstone in the construction and manufacturing sectors due to their exceptional strength and reliability. Unlike welded pipes, seamless black steel pipes are manufactured without seams, making them less prone to failure under high pressure. This intrinsic characteristic allows them to maintain structural integrity in various applications, from plumbing to structural frameworks.

2. Key Benefits of Seamless Black Steel Pipes

Seamless black steel pipes offer several advantages that make them a preferred choice in many industries:

2.1 Enhanced Durability

Seamless pipes are formed from a single piece of steel, eliminating the weak points that seams can create. This results in superior resistance to stress, corrosion, and impact, ensuring longevity in demanding environments.

2.2 High Pressure Resistance

These pipes are designed to withstand high pressure, making them ideal for both residential and industrial applications. Their ability to handle extreme conditions reduces the likelihood of leaks and failures.

2.3 Versatility in Applications

Seamless black steel pipes can be utilized in a wide range of applications, from oil and gas transportation to structural components in construction. Their adaptability makes them a valuable asset across various sectors.

2.4 Cost-Effectiveness

Though the initial investment may be higher, the long-term savings associated with reduced maintenance and replacement costs make seamless black steel pipes a cost-effective choice for many businesses.

3. Applications of Seamless Black Steel Pipes in Various Industries

Seamless black steel pipes find applications in numerous industries due to their strength and versatility. Here are some key sectors where these pipes are commonly used:

3.1 Oil and Gas Industry

In the oil and gas sector, seamless black steel pipes are critical for transporting crude oil and natural gas. Their ability to withstand high pressures and corrosive substances makes them an essential component of pipelines.

3.2 Construction and Structural Applications

These pipes are widely used in construction for structural support, plumbing, and heating systems. Their reliability ensures that buildings and infrastructures maintain their integrity over time.

3.3 Automotive and Transportation

Seamless black steel pipes are utilized in automotive manufacturing for exhaust systems and other components that require high strength and durability.

3.4 HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often incorporate seamless black steel pipes due to their ability to handle high temperatures and pressures without compromising performance.

4. The Manufacturing Process of Seamless Black Steel Pipes

Understanding the manufacturing process of seamless black steel pipes helps illustrate their superiority over welded alternatives. The process primarily involves the following steps:

4.1 Hot Working

The manufacturing begins with heating a solid billet of steel to a high temperature. This process prepares the material to be shaped into a pipe.

4.2 Piercing

Once heated, the billet is pierced to create a hollow tube. This step is critical as it sets the foundation for the seamless pipe.

4.3 Elongation

The hollow tube is then elongated and reduced in diameter through further manipulation, shaping it into the desired specifications.

4.4 Finishing

Finally, the pipe undergoes surface treatment and quality checks to ensure it meets industry standards. This finishing process can include processes like pickling, which removes scale and other impurities.

5. Industry Standards and Specifications

To ensure the reliability and safety of seamless black steel pipes, various industry standards must be met. Key specifications include:

5.1 ASTM A106 and ASTM A53

These specifications outline the requirements for seamless carbon steel pipes used in high-temperature service and general applications.

5.2 ASME B36.10 and B36.19

These standards dictate the dimensions and tolerances for carbon and stainless steel pipes, respectively, ensuring consistency in manufacturing.

6. Maintenance Tips for Seamless Black Steel Pipes

Proper maintenance of seamless black steel pipes is crucial to prolong their lifespan and maintain structural integrity. Here are some essential tips:

6.1 Regular Inspections

Conducting routine inspections helps identify potential issues before they escalate. Look for signs of corrosion, wear, or leaks.

6.2 Proper Coating

Applying protective coatings can prevent rust and corrosion, especially for pipes exposed to harsh environments.

6.3 Appropriate Installation Practices

Ensure that seamless pipes are installed correctly to avoid undue stress and ensure optimal performance.

7. Cost-Effectiveness of Seamless Black Steel Pipes

While the upfront costs of seamless black steel pipes may be higher than their welded counterparts, they often lead to greater savings in the long run. Here’s why:

7.1 Lower Maintenance Costs

Due to their durability and resistance to failure, seamless pipes require less frequent maintenance, saving money on upkeep.

7.2 Longer Lifespan

The inherent strength of seamless black steel pipes translates to a longer lifespan, reducing the need for replacements.

7.3 Enhanced Efficiency

The ability to handle high pressures and temperatures means fewer disruptions in operations, leading to increased efficiency and productivity.

8. Future Trends in Seamless Black Steel Pipe Usage

The demand for seamless black steel pipes is expected to continue growing as industries evolve. Key trends include:

8.1 Increasing Environmental Regulations

As industries face stricter environmental regulations, the demand for durable and reliable piping solutions will likely rise, making seamless black steel pipes a favored choice.

8.2 Technological Advancements

Innovations in manufacturing processes and materials may enhance the properties of seamless pipes, providing even greater strength and durability.

8.3 Growth in Renewable Energy

The renewable energy sector’s growth, particularly in wind and solar energy, will drive the need for robust piping systems to support new infrastructure.

9. Frequently Asked Questions (FAQs)

9.1 What are seamless black steel pipes used for?

Seamless black steel pipes are primarily used in high-pressure applications, including oil and gas transportation, construction, and HVAC systems.

9.2 How do seamless pipes differ from welded pipes?

Seamless pipes are manufactured without seams, making them more durable and resistant to pressure compared to welded pipes, which can have weak points at the seams.

9.3 Are seamless black steel pipes prone to corrosion?

While seamless black steel pipes are strong, they can still corrode if not properly maintained. Applying protective coatings can help reduce this risk.

9.4 What are the common sizes of seamless black steel pipes?

Seamless black steel pipes come in various sizes, typically ranging from 1/8 inch to 36 inches in diameter, depending on the application.

9.5 How can I ensure the quality of seamless black steel pipes?

To ensure quality, always source pipes from reputable manufacturers who adhere to industry standards and specifications, such as ASTM and ASME.

10. Conclusion

Seamless black steel pipes are an invaluable choice for ensuring structural integrity across various applications. Their unique manufacturing process, coupled with their inherent strength and reliability, positions them as a preferred option in industries ranging from construction to oil and gas. As we look to the future, ongoing innovations and a growing focus on sustainability will likely enhance the role of seamless black steel pipes in modern infrastructure.

By choosing seamless black steel pipes, industries can invest in long-lasting solutions that not only meet but exceed expectations for performance, safety, and cost-effectiveness.

TAG:

Related Posts

The Essential Guide to Cold Drawn Seamless Tubing in Construction

Cold drawn seamless tubing is a critical component in various construction and decorative applications, offering superior strength and adaptability. Unlike welded tubes, seamless tubing is manufactured without joints, which enhances its durability and reduces the likelihood of structural failures. This makes it an ideal choice for environments that require enhanced mechanical properties and resist